Falls, slips, and trips are a leading cause of workplace injuries across all general industry environments, and property management teams are no exception. Whether on rooftops, in stairwells, mechanical spaces, or around exterior walking surfaces, these hazards remain a persistent source of serious incidents.

According to the U.S. Bureau of Labor Statistics (BLS), there were 885 fatal work-related injuries in 2023 caused by falls, slips or trips across all sectors. At the same time, the Occupational Safety and Health Administration (OSHA)’s Fall Protection standard (29 CFR 1926.501) remains the most-frequently cited violation for more than a decade, with over 7,000 violations in FY 2023. A single willful or repeated violation can incur penalties up to $165,514 per violation.

Beyond compliance, fall protection is a critical responsibility for building owners and managers who must safeguard the people who service, maintain, and access their properties every day.

That’s why we offer our Rooftop Safety Audit, a proactive and comprehensive approach to identifying and mitigating risks before incidents occur. Through a single, detailed site assessment, our team pinpoints hazards, evaluates the performance of existing protection systems, and delivers a clear, prioritized mitigation plan complete with budget-ready recommendations. The result is a practical roadmap that empowers property teams to protect their people, reduce liability, and make informed, confident safety investments.

Inside the Rooftop Safety Audit: The Complete Breakdown

Our Rooftop Safety Audit was built for property teams who need answers, not more questions. One comprehensive site visit delivers engineered solutions, budget-ready recommendations, and documentation designed to withstand OSHA scrutiny.

What the Audit Delivers

Every Rooftop Safety Audit includes five core deliverables that move property teams from assessment to action:

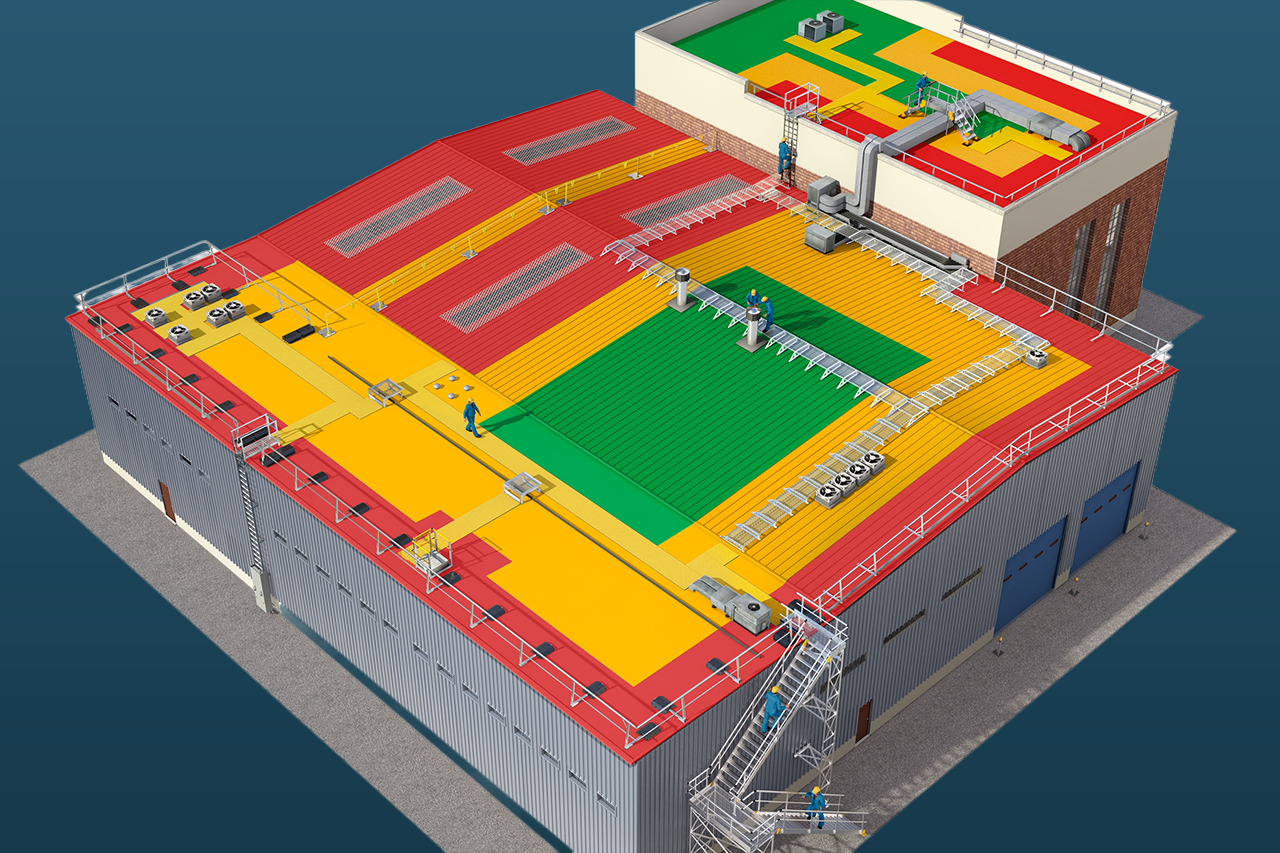

- Aerial View of Your Facility: A bird’s-eye map showing risk zones across your entire campus. Property managers with multiple buildings can finally prioritize rooftop safety investments based on actual exposure rather than guesswork.

- Individual Roof Solution Designs: Engineered drawings tailored to each roof’s specific hazards and access requirements. Our designs take into account your HVAC layout, existing anchor points, and operational constraints.

- Compliance Checklist by Roof: Findings tied directly to OSHA and ANSI standards. When an inspector arrives, you’ll have line-item documentation of what’s compliant, what’s planned, and what’s in progress.

- Budgets by Priority and Risk: Capital and operating expense breakdowns that help directors allocate funds based on actual liability exposure, not just the loudest voice in the meeting.

- Comprehensive Audit Report: A complete summary with timelines, next steps, and the documentation your insurance carrier and legal team need when questions arise.

The Five-Step Assessment Process

Our audit also follows a systematic approach that examines how workers access your roof, where they walk once they’re up there, and what hazards exist along the way.

1. Roof Access Evaluation

Most falls happen during access and egress. Our team inspects ladder conditions, hatch integrity, and fixed stair compliance to confirm workers can reach the roof safely.

2. Access Point Fall Hazard Assessment

Workers climbing onto a roof face immediate exposure to edges and elevation changes. We identify any fall hazards at or near access points that meet the four-foot threshold requiring protection.

3. Designated Walkway Mapping

Safe routes may not be obvious on most rooftops. We will map and recommend marked paths that avoid skylights, mechanical obstacles, vents, and unprotected edges.

4. Equipment Proximity Analysis

Maintenance teams service HVAC units and rooftop equipment without realizing how close they are to unprotected edges. We flag any equipment within six feet of a drop and identify units on low-slope roofs that fall within the 15-foot caution zone.

5. Unprotected Edge Documentation

Any drop of four feet or more requires fall protection under OSHA standards. We document every unprotected edge and recommend compliant guardrails or engineered controls based on roof type and operational use.

Eliminating Rooftop Safety Uncertainty

Many property teams struggle to get clear answers to three critical questions: Are we compliant? Can we document it? And what happens if OSHA shows up tomorrow?

Our Rooftop Safety Audit eliminates that uncertainty. It provides a clear, site-specific understanding of which rooftops need immediate attention, which hazards can be addressed over time, and exactly what documentation is required when regulators or insurance carriers request proof.

Whenever possible, we coordinate audits alongside anchor inspections, allowing both requirements to be completed in a single site visit. That means less disruption, fewer vendors to manage, and a more streamlined compliance process.

Without this clarity, teams are often left guessing. Property managers inherit buildings with outdated or missing fall protection documentation. Engineering groups are forced into reactive fixes after near misses. And budget discussions stall because no one can quantify the actual risk or prioritize safety investments with confidence.

When to Schedule Your Audit

Rooftop conditions change more than most property teams realize.

Schedule an audit whenever your building undergoes reroofing, equipment installations, or layout modifications that affect access routes or fall hazards. Incidents and near-misses also trigger the need for reassessment, as does turnover in your engineering or maintenance staff.

Annual audits represent the best-practice approach. Documentation stays current, budgets align with evolving risk profiles, and training protocols reflect actual rooftop conditions for new hires. Compliance isn’t a one-time checkbox. Regular audits keep your team ahead of liability, rather than reacting to citations.

Three Ways Our Rooftop Safety Audit Pays Off

Our Rooftop Safety Audit converts findings into action. You’ll walk away with compliance documentation, portfolio-wide consistency, and risk reduction.

1. Meet Compliance Requirements

Our audit delivers the analytics, documentation, pricing, and prioritized timelines that property teams need to achieve full OSHA compliance. No vague recommendations or generic checklists. You’ll have a defensible plan with clear deadlines tied to actual liability exposure.

2. Standardize Systems Across Your Portfolio

Buildings with consistent fall protection systems are easier to train on, cheaper to maintain, and simpler to budget for. Property managers overseeing multiple sites can now implement uniform safety protocols instead of managing a dozen different configurations that require specialized knowledge and vendor relationships.

3. Minimize Risk and Liability Exposure

Well-designed, properly maintained fall protection systems significantly reduce accidents and compliance failures. When equipment functions reliably and teams know how to use it, the likelihood of incidents drops—along with downtime, workers’ comp claims, and the repeat violations that lead to compounding OSHA penalties.

The Differentiators – What Sets This Audit Apart

Falls remain one of OSHA’s most frequently cited hazards, and rooftop risks often hide in plain sight—access ladders, unprotected edges, mechanical units installed too close to drop-offs, and aging equipment. Annual audits give property teams the clarity they need to identify issues early and resolve them long before citations or claims become a problem.

We work closely with property teams from assessment through installation, providing training and documentation, not just handing over a report and walking away. And thanks to our partnership with Kattsafe, we provide access to engineered height-safety systems built for real-world rooftop conditions, rather than generic, off-the-shelf components that force costly workarounds.

Each audit delivers detailed reports, compliance checklists, and budget-ready recommendations organized by priority and risk level. This lets directors tie rooftop safety needs directly to annual capital planning, rather than scrambling for funds after a near miss or incident forces immediate action.

Want to see how the process works from start to finish? Watch our on-demand webinar for a complete walkthrough of our Rooftop Safety Audit.