Of all the building types, parking garages benefit the most from the philosophy, “early detection, early cure.” Routine preventive maintenance is a must for these structures, which are exposed to extreme stress in corrosive environments, all while supporting enormous loads.

The structural components of parking structures are directly exposed to weather and other environmental conditions. Extreme temperature changes, rain, snow, de-icing salts, road grime, and dampness directly influence the durability of parking structures and can create performance problems. In the Northeast U.S., much of the corrosion and subsequent repair can be traced to salts brought in by vehicles during the winter months.

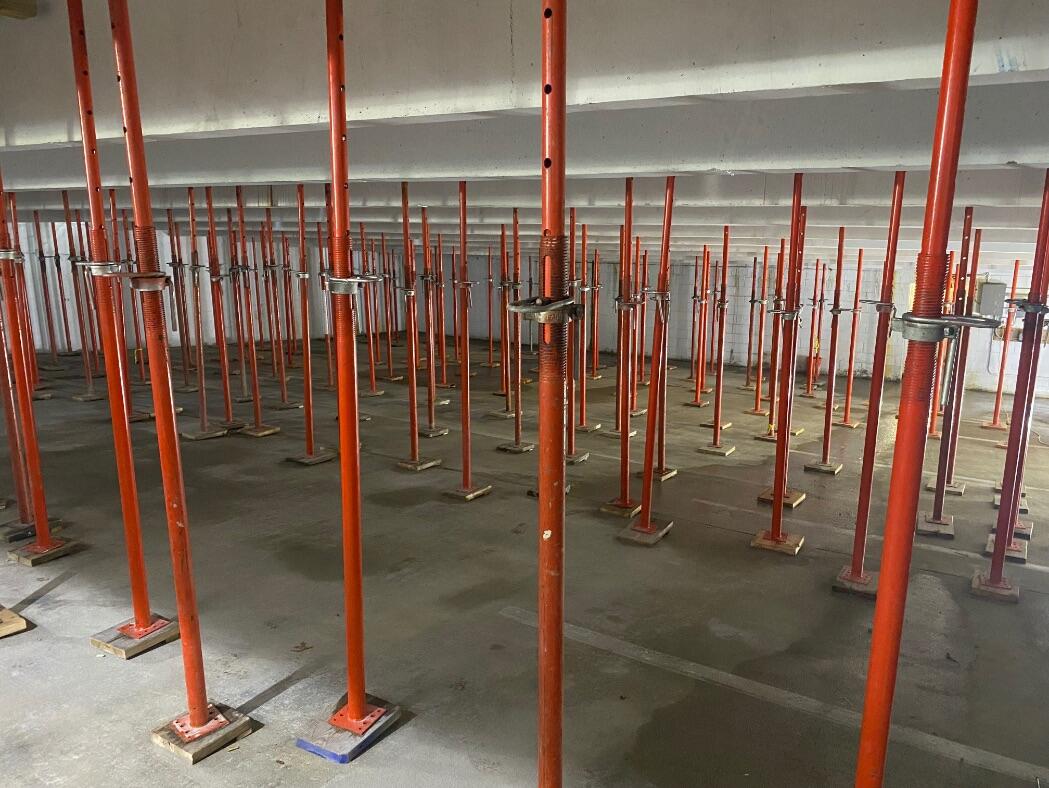

Garage restoration and repair are very different challenges than those found elsewhere in a building. Because most garages need to be kept open and operational, phasing plans and protection of parked cars are key elements in any successful garage repair project. If the concrete cracks or expansion and control joints fail, water can penetrate the interior of the parking structure. This speeds up corrosion and oxidation of the reinforcing steel, potentially leading to premature failure of the structural elements. Implementing a proper preventive maintenance program will prolong the life expectancy of these elements of your parking garage.

Parking garages are typically low on the priority list and often regular maintenance is deferred or ignored. But early detection of minor water infiltration is essential to mitigating greater structural issues that can lead to large capital expenses for building owners. Some easy signs to spot an issue are:

- Concrete cracking and spalling

- Concrete erosion

- Exposed rebar

- Rust

- Oxidation

- Deteriorated expansion joints

- Sloping or warping

Inspect your parking garage annually, or better semi-annually, and document its conditions. Use a camera to take good, accurate photos of your garage. Mark any problems on the photos when they’re taken. During the next re-inspection, check to see if any issues have gotten worse. If so, contact a qualified restoration contractor like Valcourt Group, or an experienced engineering consultant, to make a repair recommendations. Inspections should include:

- Concrete decks

- Overhead/underside of concrete decks

- Beams and columns

- Bearing pads

- Joints between construction elements

- Sealants

- Exposed steel

- Masonry/stucco/fireproofing

- Post tensioning

- Barrier cables

Many structural problems, if monitored on a regular basis, can be properly budgeted for in a normal maintenance plan instead of as an emergency capital expenditure. On average, you can plan to budget 10% – 20% of annual operation costs for cleaning and minor repairs in your parking garage. Keeping your garage properly maintained also includes regular sweeping and debris removal plus clear, visible striping. These efforts will contribute to the aesthetic value of the garage and also the safety of tenants, personnel and patrons. Safety during construction as well as minimal disruption to daily operations are important factors of a parking garage project. Hiring a contractor who understands and addresses these items is a good first step.